With us you will find the blades,

with which you can cut successfully

LUTZ BLADES manufactures blades and knives for industrial applications throughout the American market – from razor-sharp for the finest cuts to extremely robust for impact and pressure cuts.

To find the optimal solution for every cutting task, we work closely with our customers to define all relevant parameters that help meet their individual requirements perfectly – for greater sharpness and longer blade life.

Materials tailored to the application, the tightest geometry tolerances, high-performance coatings, and deep manufacturing expertise – with this combination, we provide our customers across the U.S. with exactly what they’re looking for: blades that last longer and cut more efficiently.

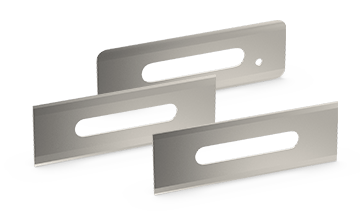

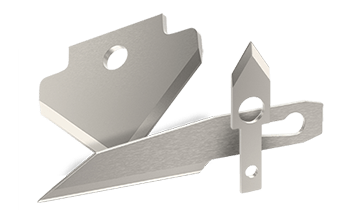

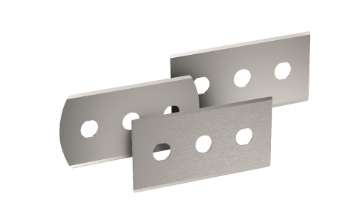

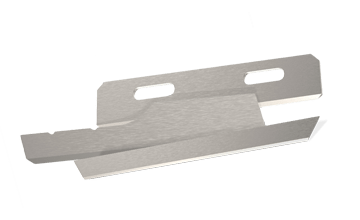

More about usBlades by shape

by LUTZ BLADESThe application areas of our blades:

In use everywhereWhether for the food industry or for car manufacturers, whether in medical technology or in trade – LUTZ BLADES produces around 1,500 different standard blades and about 500 special blades according to customer requirements for the American market and for industries around the world.

Worth knowing

all about LUTZ BLADES

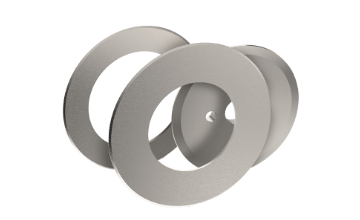

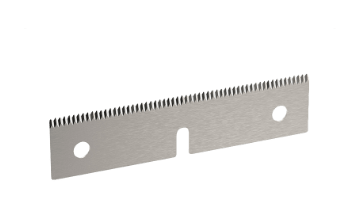

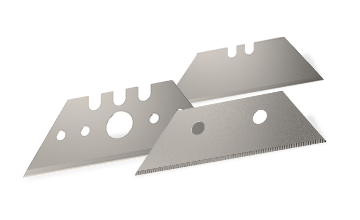

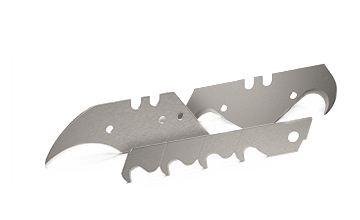

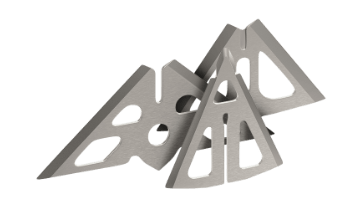

Cutting molds

Whether 1- or 2-edged, whether with one, two or three facets, whether concave or convex – you can be sure that at LUTZ BLADES you will find exactly the blade shape you need for your tasks.

Sliding and hard coating

The sliding and hard coating is essential for the quality of every blade. Our experts will recommend the coating that best suits your cutting application, your cutting environment and your production process.

Materials

There is a large selection of basic materials for blade production. The trick is to select precisely the material that best meets all requirements. And this is where LUTZ BLADES regularly scores with its decades of experience.

Sharpness

A special feature of LUTZ BLADES blades is their extreme sharpness. Customers who work with our blades can benefit from greater efficiency, better quality and longer production times in their work processes.

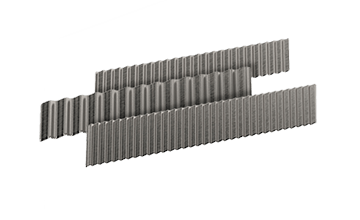

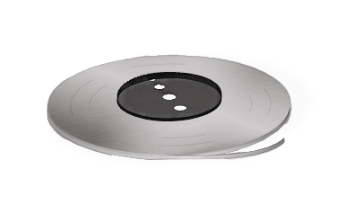

Packaging systems

Sales-active, safe, user-friendly – our packaging systems make it clear that we put a lot of thought into more than just our blades.